MIL-PRF-15733J

4.6.2 Seal. (when specified; see 3.1).

4.6.2.1 Liquid-filled units (see 3.5.1). Liquid-filled filters shall be heated in an oven at the maximum operating

temperature (see 3.1) for not less than three hours for filters weighing 20 pounds or less, and for not less than six

hours for filters weighing over 20 pounds.

4.6.2.2 All other units ( see 3.5.2). Filters shall be tested in accordance with method 112 of MIL-STD-202, and as

follows:

a. For filters having a maximum operating temperature rating of +125°C: Test condition A or D.

b. For filters having a maximum operating temperature rating of +85°C: Test condition A or D except that

the bath temperature shall be +85°C +3°, -0°C.

4.6.3 Capacitance to ground (when specified; see 3.1) (see 3.6). Capacitance to ground shall be measured in

accordance with method 305 of MIL-STD-202. The following details shall apply:

a. Test frequency: 1,000 ±100 Hz.

b. Limit of accuracy: Within ±2 percent.

4.6.4 Temperature rise (see 3.7). Filters shall be suspended by their terminals and shall be energized with rated

current at maximum rated frequency in still air (see 3.1). Lead wires shall be of copper, 6 inches (162.40 mm) long,

and of the size specified in table VII. After thermal stability has been reached and while the filter is still energized, the

maximum hotspot on the filter case shall be determined by the use of thermocouples. Lead wires specified in

accordance with table VII, shall be the smaller of the wire specified per table VII or the actual wire size of the filter

terminal.

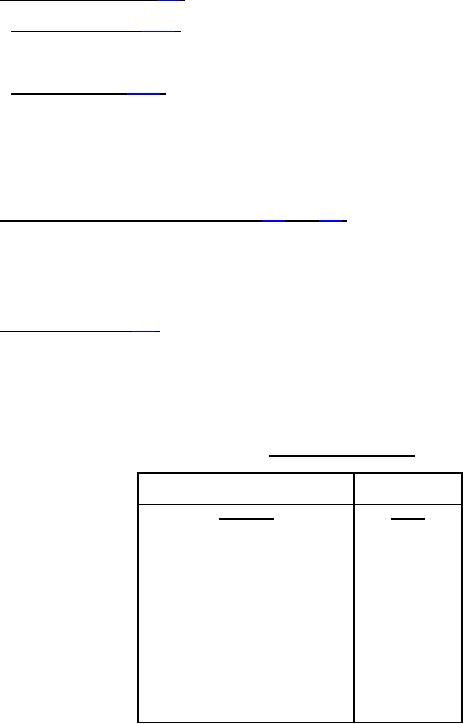

TABLE VII. Maximum lead wire size.

Rated current

Wire

of filters

size

Amperes

AWG

Up to 3

24

3+ to 5

22

5+ to 11

20

11+ to 16

18

16+ to 22

16

22+ to 32

14

32+ to 41

12

41+ to 55

10

55+ to 73

8

73+ to 101

6

101+ to 135

4

135+ to 181

2

181+ to 211

1

12

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business