MIL-PRF-15733J

3.4.2 Case. Filters shall be enclosed in a suitable case in order to pass the performance requirements of this

specification. The case shall be hermetically sealed or nonhermetically sealed as specified (see 3.1). The case shall

protect the filter components from damage under all test conditions specified and prevent leakage of impregnant or

filling compound. All metallic surfaces shall be free from insulating finishes except as specified.

3.4.3 Finish. All exposed metallic surfaces (case, hardware, and terminals) shall be suitably protected against

corrosion by plating, solder coating, or other means. The finish shall provide good electrical contact when used on a

terminal or as a conductor (see 6.4); shall have uniform texture and appearance; shall be adherent; and shall be free

from blisters, pinholes, and other defects that may affect the protective value of the coating. Pure tin plating is

prohibited (see 3.3.2). When used, tin plating shall have a minimum lead content of 3 percent (see 3.3.2 and 6.5).

3.4.4 Threaded parts. Unless otherwise specified, all threaded parts shall be in accordance with FED-STD-H28.

3.4.5 Weight (when applicable). Filters shall not exceed the weight specified (see 3.1).

3.5 Seal (when specified; see 3.1).

3.5.1 Liquid-filled units. When filters are tested in accordance with 4.6.2.1, there shall be no evidence of liquid

leakage.

3.5.2 All other units. When filters are tested in accordance with 4.6.2.2, there shall be no continuous stream of

bubbles emanating from the filter, nor shall there be any evidence of leakage of compound from the body of the filter.

3.6 Capacitance to ground (when specified; see 3.1). When filters are tested in accordance with 4.6.3, the

capacitance to ground shall be as specified.

3.7 Temperature rise. When filters are tested in accordance with 4.6.4, the maximum temperature rise shall be as

specified (see 3.1).

3.8 Dielectric withstanding voltage. When filters are tested in accordance with 4.6.5, there shall be no breakdown,

flashover, or impairment of any characteristic qualities sufficient to cause failure of the filter.

3.9 Barometric pressure (reduced). When filters are tested in accordance with 4.6.6, there shall be no breakdown,

flashover, or impairment of any characteristic qualities sufficient to cause failure of the filter.

3.10 Insulation resistance (terminal to ground). When measured in accordance with 4.6.7, the insulation

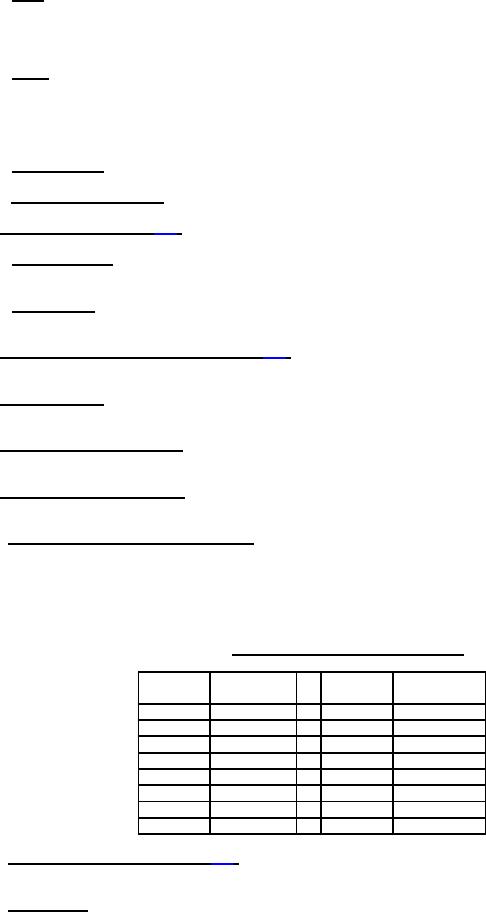

resistance of any filter section shall be not less than the applicable value shown on figure 1 or as specified (see 3.1).

The value of insulation resistance varies with temperature, and it is necessary to apply a correction factor to

measurements made at a temperature other than 25°C. Correction factors for measurements made at temperatures

between 20°C and 35°C are given in table I. The required value of insulation resistance shall be multiplied by the

correction factor to determine the new value required at the test temperature.

TABLE I. Insulation-resistance correction factors.

Degrees

Correction

Degrees

Correction

celsius

factor

celsius

factor

20

1.42

28

0.82

21

1.33

29

0.76

22

1.24

30

0.71

23

1.16

31

0.67

24

1.08

32

0.63

25

1.00

33

0.59

26

0.94

34

0.55

27

0.87

35

0.51

3.11 Voltage drop (when specified; see 3.1). When filters are tested in accordance with 4.6.8, the voltage drop

shall be as specified (see 3.1).

3.12 Insertion loss. When filters are tested in accordance with 4.6.9, the insertion loss shall be as specified (see 3.1).

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business