MIL-PRF-15733J

reworked to correct the defects. After screening and removal of defects, or rework as applicable, a new sample of

parts shall be randomly selected in accordance with table V and subjected to the group A inspection. Such lots shall

be clearly identified as re-inspected lots. If one or more defects are found in the second sample, the lot shall be

rejected and shall not be supplied to this specification.

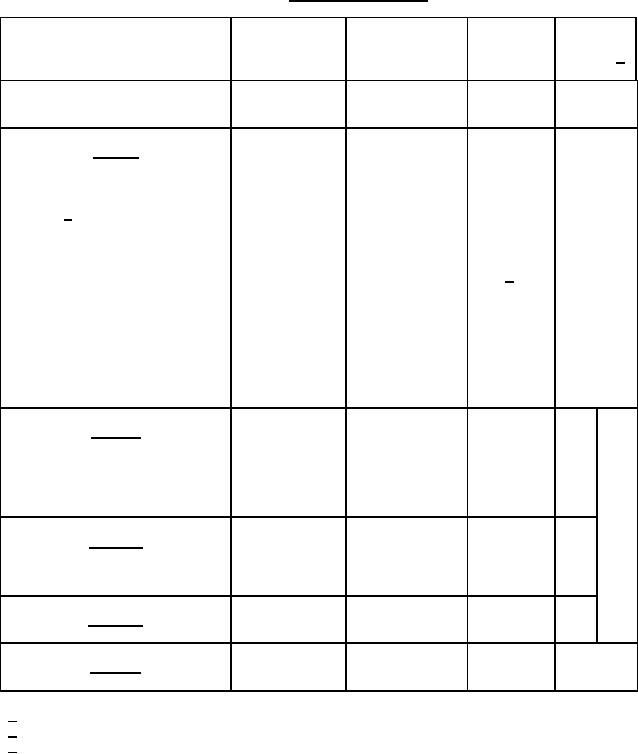

TABLE III. Qualification inspection.

Number of

Number of

Inspection

Requirement

Test method

sample

defectives

allowed 1/

Paragraph

paragraph

units to be

inspected

Flashpoint of impregnant or

---

0

potting compound

Group I

Visual and mechanical

examination:

Material, design, construction,

3.4.5 incl,

marking 2/, and workmanship

Seal

Capacitance to ground

(when specified)

Temperature rise

3/

Dielectric withstanding voltage

24

1

Barometric pressure (reduced)

Insulation resistance

(terminal to ground)

Voltage drop

Insertion loss

Overload

Terminal strength

Group II

Resistance to soldering heat

(soldered terminals only)

Resistance to solvents

4

1

Salt atmosphere (corrosion)

Thermal shock and immersion

Group III

Shock, specified pulse

2

Vibration

4

1

Moisture resistance

Group IV

Life

10

1

Group V

0

Solderability

5

1/ A sample unit having one or more defects will be charged as a single defective.

2/ Marking will be considered a defect only if it becomes illegible as a result of the inspection.

3/ One additional sample unit is included in each sample of 24 to permit substitution for the allowable

defective in group I.

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business