MIL-PRF-15733J

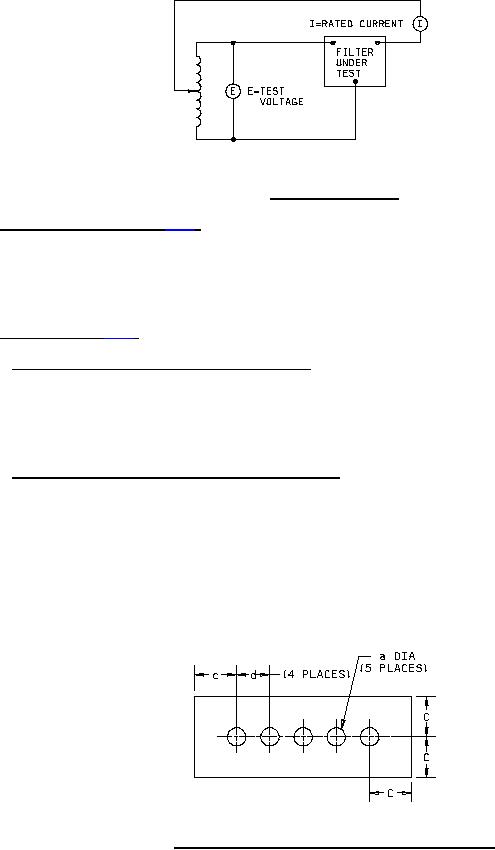

FIGURE 4. Typical life test circuit.

4.6.20 Resistance to solvents (see 3.23). Filters shall be tested in accordance with method 215 of MIL-STD-202.

The following details shall apply:

a. The marked portion of the filter body shall be brushed.

b. Filters shall be visually examined for evidence of mechanical damage and legibility of marking.

4.6.21 Solderability (see 3.24).

4.6.21.1 Solderability of terminals (soldered terminals only). Filters shall be tested in accordance with method 208

of MIL-STD-202. The following details and exceptions shall apply:

a. Number of terminations to be tested: 2.

b. Special preparations of terminations: None.

4.6.21.2 Solderability of mounting termination (when applicable). Filters shall be tested as follows: (Note: The

terminal solderability test (see 4.6.21.1) should be done with the filters already soldered to the test coupon; however,

if the size of the solder pot or variations in the terminal preclude this sequence, the terminal solderability may be done

first).

a. Filters shall be soldered to the test coupon shown on figure 5. The filters shall be soldered with an iron

at 253°C ± 7°C using PB36AWB6 or PB36AWB7solder in accordance with J-STD-006. The test coupon

shall be preheated to 100°C ± 7°C. Heat should be applied to the coupon first in the immediate vicinity of

the filter. The tip of the iron should then be moved so that it comes in contact with the edge of the filter

for no more than 5 seconds or until a smooth solder fillet has been established around the filter. This

sequence will be repeated with each filter.

FIGURE 5. Test coupon for solderability of mounting terminations.

18

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business