MIL-PRF-28861D

4.6.8.1 Alternative x-ray system and procedures. The manufacturer has the option, with qualifying activity

approval, to use an alternative x-ray system, such as real-time x-ray, and procedures to inspect for the defect criteria

specified. This alternative system and procedures shall meet the applicable requirements of method 209 of MIL-

STD-202 and 4.6.8 herein except that radiographic image-quality indicators, as specified in 4.6.8b, may be used at

the beginning and end of each inspection lot provided equipment settings are not modified. This alternative system

and procedures shall be documented in the manufacturer's MIL-STD-790 compliance program.

4.6.9 Seal (hermetically sealed filters only) (see 3.14). Filters shall be tested in accordance with method 112 of

MIL-STD-202. The following details shall apply:

a. Class B filters: Filters shall be tested in accordance with test condition A or D.

b. Class S filters: Filters shall be tested in accordance with test condition C, procedure IIIa. Following this

test, filters shall be tested in accordance with test condition A or D.

4.6.10 Voltage and temperature limits of capacitance (see 3.15). This test may be performed in conjunction with

the insertion-loss (at temperature) test, see 4.6.5.1. The test conditions and capacitance measurements shall be in

accordance with 4.6.4, except that the chamber temperature shall be accurate to ± 2°C. After an initial capacitance

measurement at +25°C, a dc voltage equivalent to the rated dc voltage or 1.4 times the rated rms voltage shall be

applied to the filters as the capacitance is measured. (Note: The dc voltage shall not exceed 500 V dc and the

terminals shall be positive with respect to the case.) The capacitance shall then be measured at -55°C, -30°C,

+25°C, +85°C, and +125°C. (Note: The filters shall be stabilized for a minimum of 30 minutes at each temperature

before a measurement is taken.)

4.6.11 Temperature rise (see 3.16). Filters shall be suspended by their terminals and energized with rated

current at maximum rated frequency (see 3.1) in still air. Lead wires shall be of copper, 6-inches long (152.4 mm),

and of the size specified in table IX. After thermal stability has been reached and while the filter is still energized, the

maximum hotspot on the filter case shall be determined by the use of thermocouples. Lead wires specified in

accordance with table IX, shall be the smaller of the wire specified in accordance with table IX or the actual lead wire

size of the filter terminal.

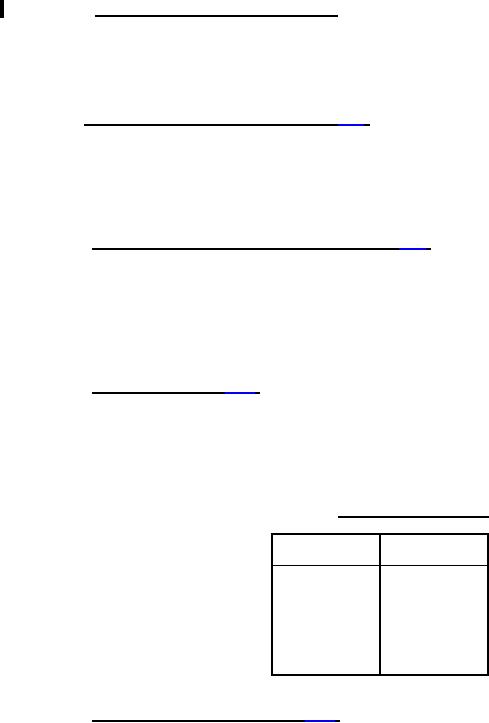

TABLE IX. Maximum lead wire sizes.

Rated current

Wire size

of filter

Amperes

AWG

Up to 3

24

3+ to 5

22

5+ to 11

20

11+ to 16

18

16+ to 22

16

22+ to 32

14

4.6.12 Barometric pressure (reduced) (see 3.17). Filters shall be tested in accordance with method 105 of

MIL-STD-202. The following details shall apply:

a. Method of mounting: Securely fastened by normal mounting means.

b. Test condition letter E (150,000 feet).

c. Test during subjection to reduced pressure: Dielectric withstanding voltage as specified, except that the

test voltage shall be 125 percent of the rated voltage.

25

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business